GCS 6000 Tempreature Logging System

The GCS6000 is a complete temperature monitoring package with data logging capabilities for producing storage data used by fruit export programs. Up to six high-accuracy fruit storage temperature sensors can be installed in each room and will log data hourly to removable flash media (SD Card) as well as a PC if desired. Using the PC interface, data can be displayed and printed using the secure Windows software. The GCS temperature sensors have been a staple in fruit storage data logging for over two decades due to their ultra-high accuracy and stability, even while long distance wire runs may be present.

Fetures

- Monitor and Record Temperature Data for Export

- View Temperatures at Various Points in the Storage Room.

- Color Touch-Screen for PLC Interface

- Standard 24 Probe Inputs using GCS 28B Probe

- Upgradable to Control Oxygen and Carbon Dioxide

- Temperature Data can Ethernet to SCS KiloWatch Energy Management System

Other features of the GCS6000 are the ability to transfer the temperature data between other devices, as well as using it as a complete CA controller. Upgrades are as simple as adding I/O modules to the main controller, so upgrades can be done when the time is right for you. The system also communicates with Dixell thermostats that are used either as freeze protection or temperature controllers, allowing the user to view and modify room temperatures and setpoints from a central location. Through this network of devices, the system can even grow into your energy management controller. When paired with the GCS KILOWATCH Energy Management System,

electrical demand management and ultimate refrigeration control translates to huge energy savings to you.

GCS Temperature Probes

The GCS temperature measuring system is based on the tested and proven standards that have been used successfully for over 20 years in Cold and CA fruit and vegetable rooms throughout the world. The GCS system uses a precision thermistor network to provide an accurate, high stability and linear output. The sensor is embedded into a rugged aluminium housing which has 3 layers of moisture sealing and encapsulation.

The sensors are connected through an accurate and proprietary interface to an industrial PLC control system. This provides interconnection with industry standard SCADA display and recording systems or can be used with an interface provided to a Access™-database recording and analysis system.

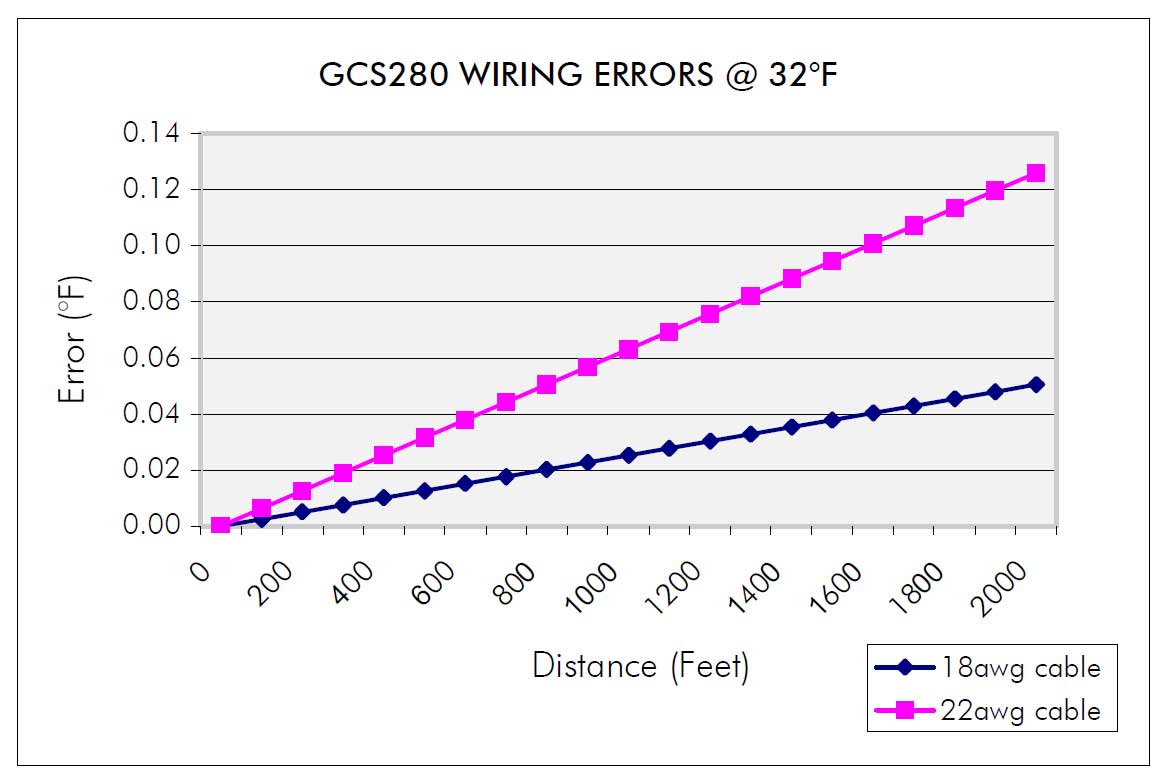

The fundamental resistance is high which dramatically reduces installed errors due to wiring resistance, allowing simple multicore cables to be used.

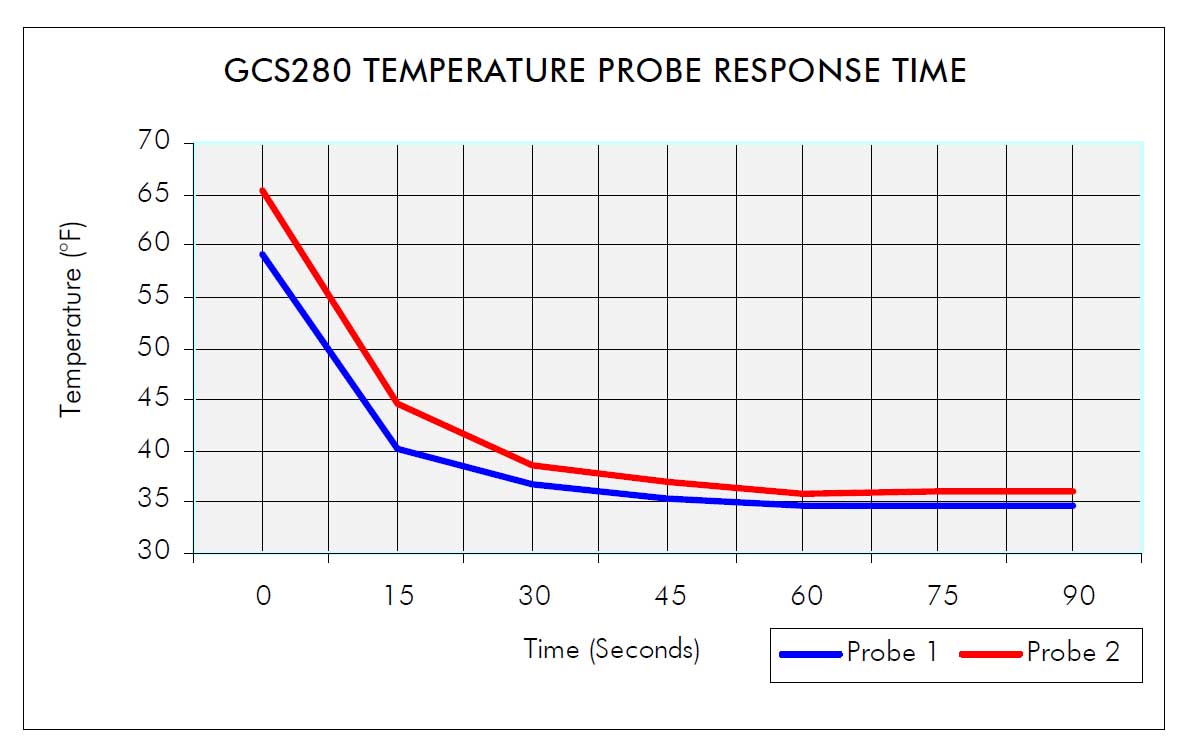

Temperature readings become stable after 60 seconds, easily meeting the 3:00 requirement 2.3.2b in the Mexico work plan.

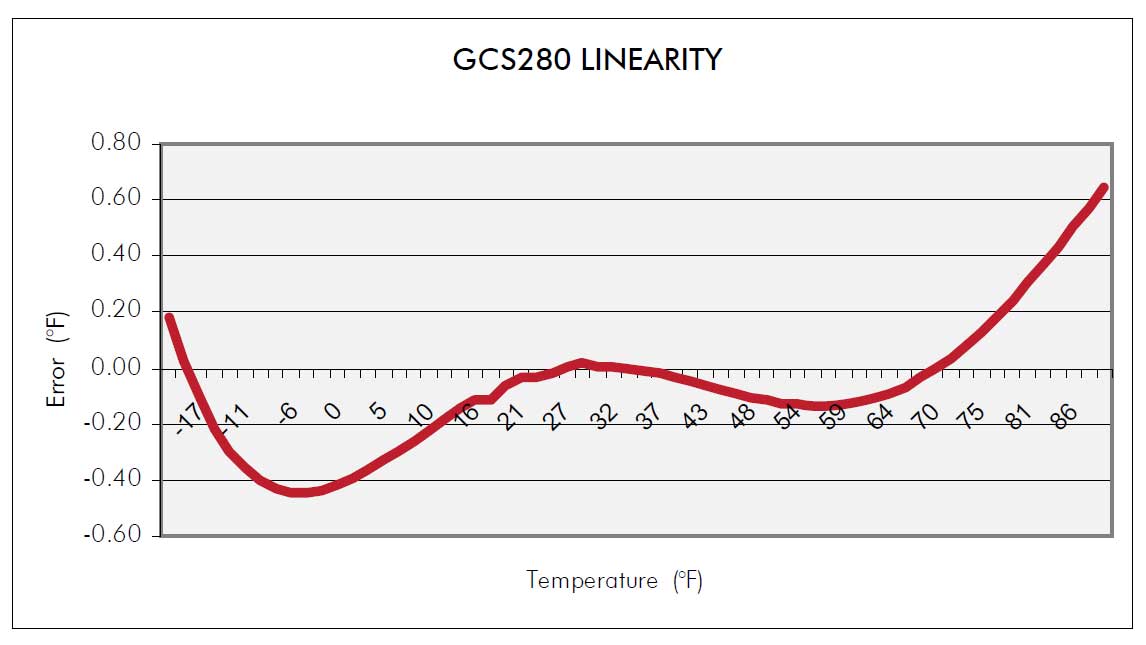

The design of the thermistor network within the probe, combined with the interface within the measuring electronics, provides a substantially linear output over the temperature ranges relevant to fruit storage applications.

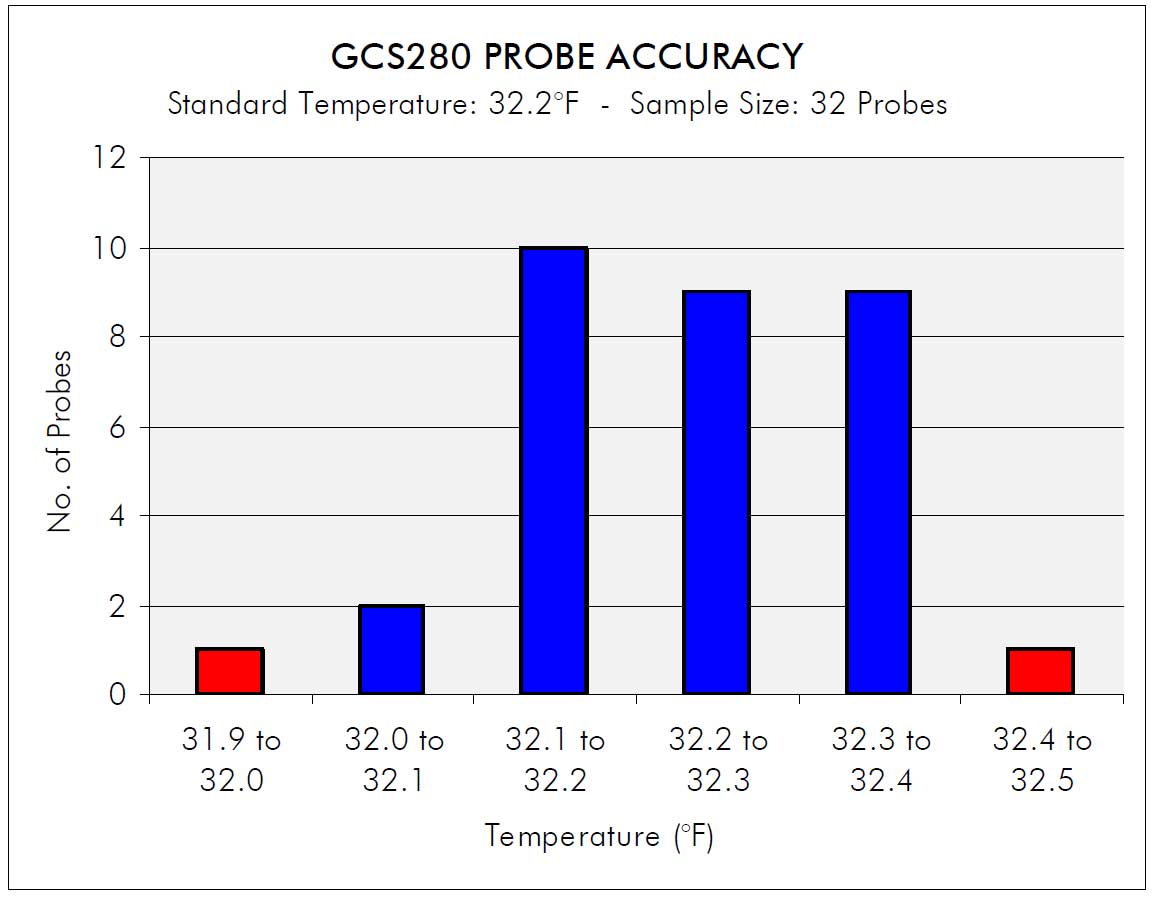

It can be seen that, while being well within the ±1°F requirement of the specification 2.3.2a, only two of the 32 tested probes were outside of the GCS standards (±0.2°F) and thus were rejected.